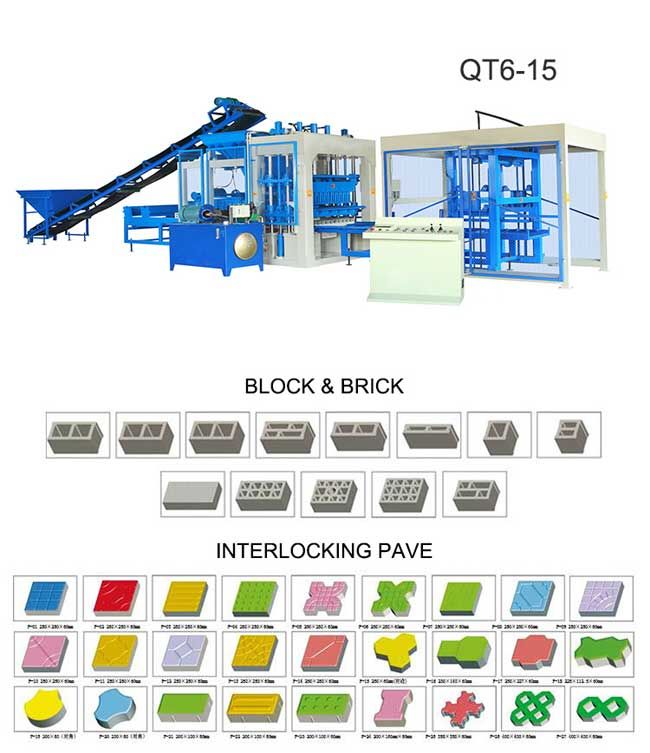

Model: QT6-15

Molding cycle: 15-20S

Capacity: 1440Pcs/Hr

Power: 29kw

Each unit of the high quality qt6-15 paver block machine is independent and has good regulating performance, which is suitable for producing blocks of different proportions and types.

1. Paving brick machine a form of standard blocks, used in the supporting line, in line with the scientific palletizing system.

2. Paving brick machine beautiful and generous shape, reliable use, convenient maintenance. Automatic operation can be realized, greatly reducing the labor intensity of operators.

3. Can configure the color cloth system, can produce high quality color wall block and a variety of floor interlock block.

4. Closed automatic production line, advanced modular combination structure, can carry out manual, linkage and automatic equipment operation, with full automatic production line configuration of optimal function.

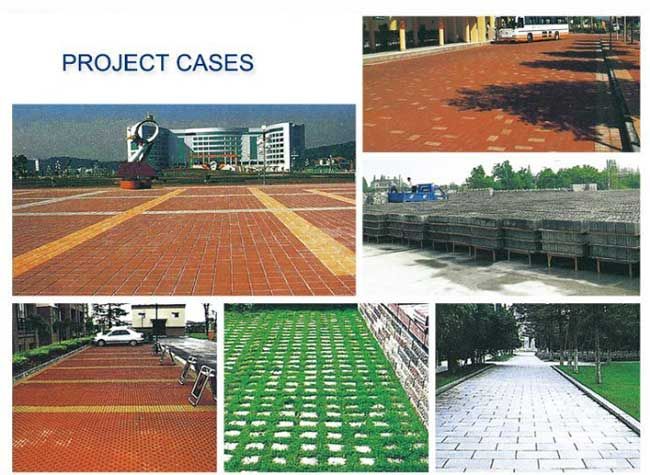

The above are other related products required by the brick machine production line. If you need it, you can contact us.

1. QT6-15 paver block machine in stock, this press broke the traditional press from the top down press, press from the bottom up, so as to overcome the old press is easy to impact, resulting in mold damage defects.

2. Because of the good exhaust performance of the new press, concrete block making machine can produce hollow brick continuously for a long time.

3. The new press adopts the control mode of internal displacement sensor, which is not affected by environmental pollution. It can accurately guarantee the external size of bricks, and make the products 100% meet the requirements of the national first-level brick standard. The cheap qt6-15 paver block machine is also equipped with internal pressure sensors, which can accurately determine the strength of bricks.

4. Paving brick brick also adopted the German Siemens company of high technology, high precision imported components and hydraulic parts, is the current domestic similar press in the higher grade of brick making machine, its speed, high output, function complete, can produce more varieties, specifications of the hollow brick, solid brick, blind hole brick, square brick, brick road pavements and other new building materials products.

5. This kind of press has low noise, consumes less electricity and can save 40% electricity.

6. The discount qt6-15 paver block machine has a high degree of automation. After setting the size and strength of bricks, the products that fail to meet the requirements can be returned to the raw material warehouse automatically, and then pressed after mixing, so as to ensure the quality to the maximum extent.

The price of paving brick making machine is only 1/3 of that of similar products abroad.

If there is no type of brick/block you need to produce above, you can send us your requirements. Our factory has a customized brick machine service. We will give you feedback as soon as we receive your message.

In order to ensure the normal and efficient operation of the equipment, especially the maintenance of the pavement brick machine mold, mold as the main part of the pavement brick mechanism brick and the main loss parts, the use and maintenance of the mold is very important, directly related to the service life and use effect of the mold.

First, the establishment of discount qt6-15 paver block machine maintenance and maintenance system in line with the development of the enterprise, at the same time, the establishment of a pavement brick machine problem solving team, and the responsibility for the specific implementation of the distribution to everyone.

Second, to each repair and maintenance of the detailed process record and systematic analysis of the problem fault, in order to find out the cause of the failure in time, and study the corresponding solution.

Third, must have the spare parts storage, must be ready for each spare parts.

Fourth, in the formulation of the enterprise annual production and operation activities, make the customized qt6-15 paver block machine maintenance plan, in case of emergency.

Cement brick machine is the use of slag, slag, fly ash, stone powder, sand, stone, cement and so on as raw materials, scientific ratio, add water mixing, through the brick machine high-pressure pressing out cement brick, hollow block or color pavement brick mechanical equipment.

There are many ways to make bricks in a qt6-15 paver block machine in stock. Different brick - making methods have different brick - making effects. And commonly used is the use of hydraulic vibration molding. There are many advantages to using this method for brick-making. At the same time the production of cement brick quality is better. So what are the advantages of using hydraulic vibration molding?

Cement brick making machine can use the way of vibration molding processing up the effect is better, vibration can make the raw material dispersion more uniform, cement brick is basically no fault, the quality of the cement brick produced is also very good. The principle of cement brick machine production cycle is relatively short, can meet the needs of a short time molding, molding cement brick block number is more and the output is very large, use up more environmental protection energy saving. When customized qt6-15 paver block machine draws material more extensive, big advantage is the structure is more convenient to clean and replace, the motor in the form of external convenient heat dissipation effect is stronger, the wear resistance of cement brick machine is very significant, generally very little failure. Cheap high quality qt6-15 paver block machine combined with the ability of mechanical and electrical integration, fundamentally save manpower and material resources, can save the combination of wet and dry compaction.

Brick/Block Size | 9" x 4" x3",10" x 5" x3",8" x 4" x4" |

Brick Raw Material | Cement, Fly Ash, Sand, Stone Dust, Gysum, Lime Sludge,etc |

Usage/Application | For Making,Fly ash bricks,Concrete Blocks,Paver Blocks,Solid Blocks, Cement Blocks, Hollow Blocks |

No. Of Bricks Per Stroke | 4, 6, 8, 10,12, 14, 16 Pcs |

Pallets Size | 22" x 23" x 19mm (Thickness) |

Automation Grade | Semi or Fully Automatic |

Brick/Block Type | Solid, Interlock, Hollow, Paver |

Method | Hydraulic Pressure |

System | PLC Controlled |

Capacity(Blocks/Bricks ) | 1000-4000 pcs per hour |

Capacity per 8 Hours | 6000pcs to 40000 pcs |

Voltage | 440 Volt |

Space Required | 30 ft ( L) x 25 ft (W) x 16 Ft (H) |

Total Power Required | 22 HP to 50 HP |

Material | Mild Steel |

Accessories | Main Press Machine with Vibrator System, Rollers Pan Mixture, Belt Conveyor, Bearing Conveyor, Electronic Control Panel, Hydraulic Power Pack, Material Trolley, Hydraulic Pallets trolley. |

Treatment Time of Bricks/Blocks | Minimum of 7- 8 Days |