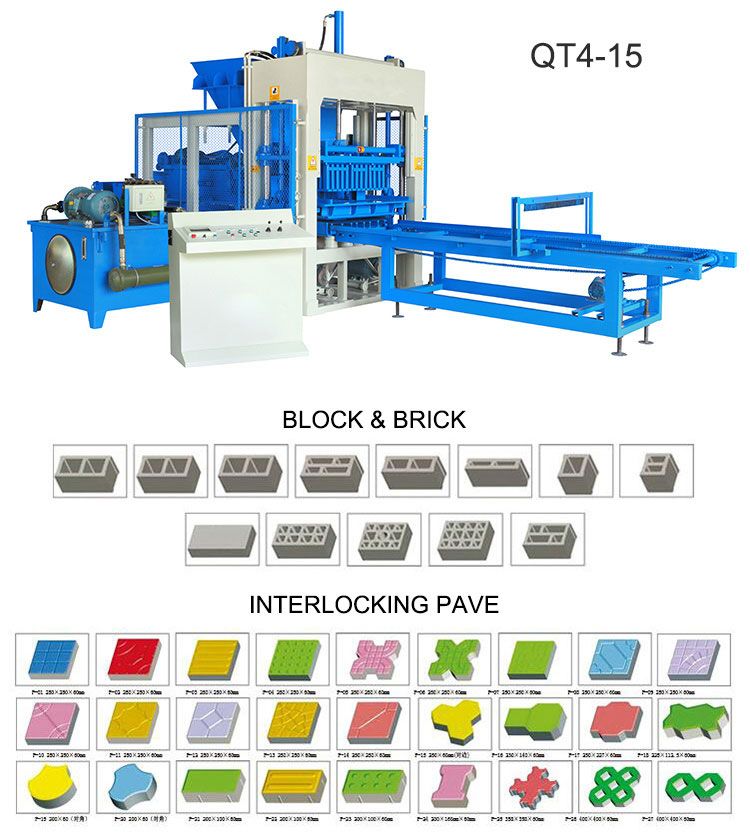

Model: QT4-15

Molding cycle: 15-20S

Capacity: 720Pcs/Hr

Power: 20kw

High quality qt4-15 fly ash brick machine is made of fly ash or other slag or ash sand as raw material, adding lime, gypsum and aggregate, by embryo material preparation, pressing molding, efficient steam curing and other processes. The complete set of equipment for autoclave fly ash brick includes: mixer, digestion bin, autoclave brick machine, wheel roller, autoclave and other main equipment, as well as auxiliary equipment such as box feeder, screw conveyor, crawler, aggregate weight, belt conveyor, maintenance car, ferrying car and so on.

The above brick making machine is the fly ash brick making machine, and there are some samples produced by the brick making machine. If you are interested, you can contact us. Of course, we can customize the brick making machine, which is determined by what type of brick you want to make.

The production process of customized qt4-15 fly ash brick machine includes several steps such as the processing and preparation of raw materials, the measurement of ingredients in a certain proportion, mixing, digestion, wheel rolling, pressing and forming, the static-stop curing of the blank, the autoclaving curing, the inspection and stacking of the finished product.

Advantages Of Fly Ash Brick Machine

The product strength produced by autoclaved cheap qt4-15 fly ash brick machine can reach MU20, the production technology level is high, the energy consumption is low, the product is widely used in building foundation and inside and outside wall. Discount qt4-15 fly ash brick machine can make use of fly ash in great quantities, and can use wet ash discharge. At least 800kg of fly ash can be used for every 1m brick, and 60,000 tonnes of fly ash can be used for qt4-15 fly ash brick machine supplier with an annual output of 50m bricks. This is undoubtedly important to save land and protect the ecological environment. Autoclaved brick has a certain scale of production and has been widely used in China.

Because autoclaved fly ash brick is the ash sand or industrial waste residue (fly ash, ore concentration, slag, gangue) as the main raw material, autoclaved fly ash brick frost resistance, corrosion resistance, compressive strength and other properties are better than solid clay brick artificial stone. The size of cheap qt4-15 fly ash brick machine is exactly the same as that of the ordinary solid clay brick, which is 240mm x 115mm x 53mm. Therefore, solid clay brick can be directly replaced by autoclave fly ash brick. It has the characteristics of light weight, heat preservation, sound insulation, heat insulation, structure science, beautiful shape, appearance size standard and so on.

Production technology of fly ash production line

The production process of qt4-15 fly ash brick machine includes several steps such as the processing and preparation of raw materials, the measurement of ingredients in a certain proportion, mixing, digestion, wheel rolling, pressing and forming, the static-stop curing of the blank, the autoclaving curing, the inspection and stacking of the finished product.

Discount qt4-15 fly ash brick machine has set off a frenzy in the current society, because its raw material is fly ash, the effective use of fly ash can reduce the environmental pressure. As the manufacturer of fly ash brick machine, HaoMei introduces the quality of fly ash brick machine.

The above picture mainly shows several models in the brick making machine. The brick making machine can generate bricks of different shapes as long as the model is replaced. If you want to customize, please send us detailed requirements.

Fly ash brick machine good quality, mainly is the use of good raw materials. Now many machines and equipment are used to make steel, but brick moulding machine has a very large characteristics, that is, its raw material is steel with a high content of steel, the density of these steel is very high, many hard objects will not leave a trace. This, of course, ensures that no raw materials will damage the machine during production. Also, the underside of the high-tech machine is much heavier than the underside, which makes the machine run without sliding, stable, and has the appropriate screws to hold it to the ground, so it's very safe.

Fly ash brick machine quality is good, mainly using the production of the customized qt4-15 fly ash brick machine is more accurate. There is no doubt that automatic use of electric motor to generate power, drive the machine operation, can greatly improve the efficiency of work. A lot of rational manufacturers in the use of electric motors, use are better power, more stable performance of the motor, so that can effectively ensure that the machine can be safe production. In addition to the motor this part, fly ash block brick machine other parts are also the best accessories, even the accuracy of each screw is very high. Each part is mutually cooperate, mutually promote, can achieve the best production condition.

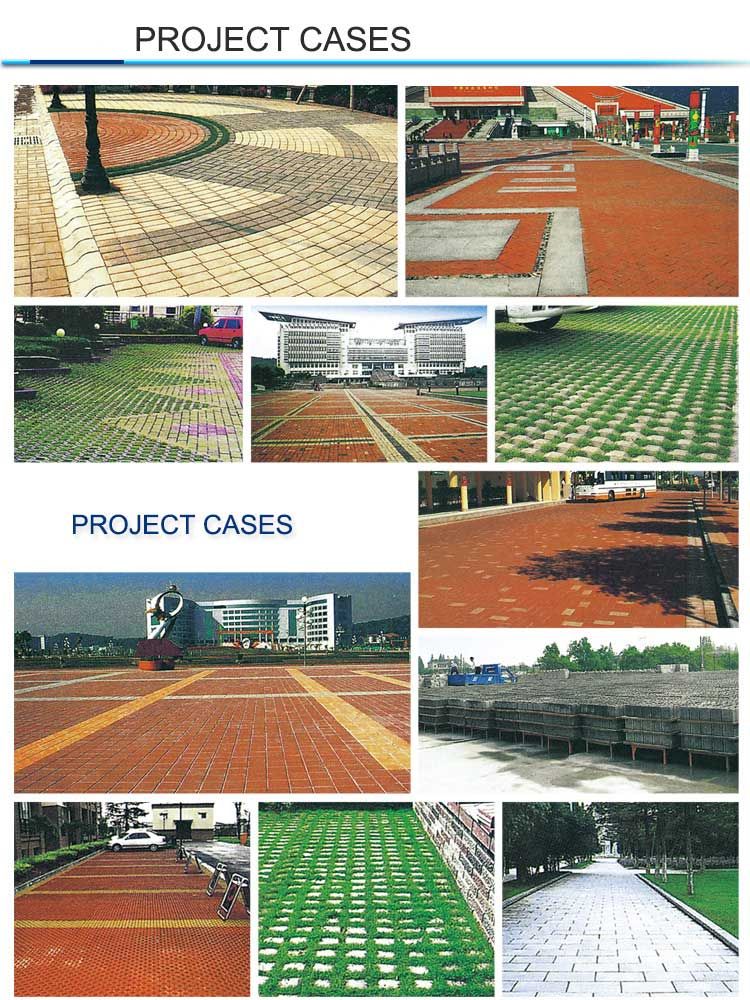

Paver brick, also known as bread brick, colored brick. The scope of application is also extensive, and can usually be used in gardens, hospitals, sidewalks on roads, parks, residential areas, etc. The picture above is part of the application. If you are interested, please contact us today.

The fly ash block brick machine is mainly produced according to the national and international production standards and has the mark of passing the safety inspection. In fact, the country attaches great importance to these automatic mechanized products, so there will be safety inspection department to check, but the fly ash brick machine in professional shops did not find any products of poor quality, so its quality is very high. The most important thing is that the country also gives special encouragement to such manufacturers, so that other manufacturers of products must learn the manufacturing process of high quality qt4-15 fly ash brick machine. Not only constantly update their products, but also continue to innovate, production of many kinds, used in many places of mechanization.

Molding cycle | 15-20s |

Production capacity | 5760~37440pcs/shift(8h) |

Vibration frequency | 4800-5100r/min |

Exciting power | 20MPA |

Overall power | 67KW |

Overall dimension | 5420*1550*2940mm |

Molding form | Vibration and Pressure |

Pallets size | 580x570x30mm |